Probe pins or spring-loaded contacts are being considered to be the fastest growing type of interconnect used by engineers. These pins are ideal for creating solderless interconnections between mating modules such as a handheld instrument to the docking station, instrument to recharger, stacking PBCs, and more! The following are reasons why SLCs are ideal for new product designs:

Probe pins or spring-loaded contact forgive to stack-up tolerances and  uneven mating surfaces.

uneven mating surfaces.

SLCs are ideal for blind mating various applications wherein the SLC only needs to mate to a gold-plated PBC base.

SLCs are without a doubt the easiest materials for engineers to use.

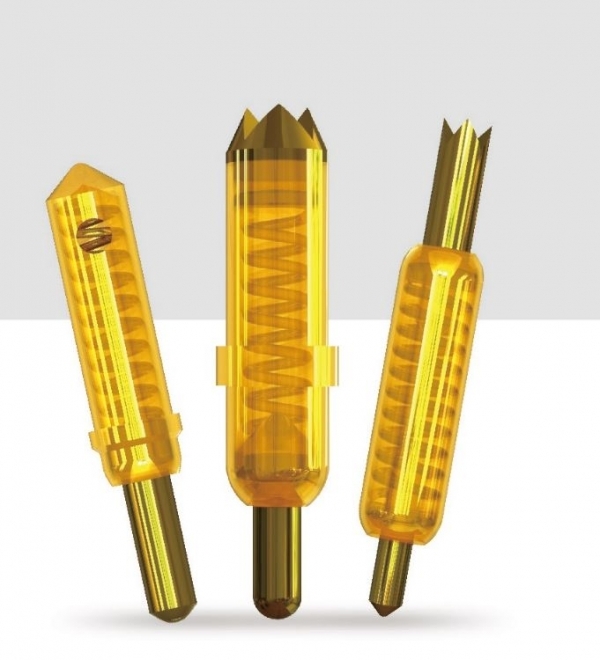

Often times, Pogo and SLC are most of the time interchanged in the community of engineers. Pogo describes being a type of SLC which is being designed with a hardened Beryllium Copper piston that is chisel, tulip, waffle, or pointed. Piercing through dielectric surfaces uses these types of SLCs, and these are being used in Bed-of-Nails test beds for high-cycling repetitive testing.

Other types of spring-loaded contacts have radius tipped pistons. Other pogo pin manufacturer uses BeCu while others use Brass. These types are more often in the docking station, recharging station, and stacking type applications. There are three uncommon styles of SLCs and the advantages of each state as follows:

- Horizontal SMT spring-loaded contacts. These types of spring-loaded contacts are ideal for low-profile designs. A good example of this type of SLCs is lighting stips such as LED which are often daisy-chained to increase its length.

- Floating Pin spring-loaded contacts. This type of spring-loaded contact is being assembled into a molded cavity that allows vertical float which will then help in applications upon uneven platforms. This style of SLC is ideal to get used as an interposer between a top and bottom PBC when both PBCs get clamped down together. This type of SLC also achieves solderless interconnection.

- Pin-in-Paste spring-loaded contacts. Emerging is the concept of assembling traditional through-hole components now using high-speed SMT pick-and-place because of the evolution of SMT assembly. Intrusive-reflow or pin-in-paste is what assembling a through-hole component onto an SMT board is being called. An SMT has a through-hole on its board while a solder paste is being screened along the annular ring of land. Instead of solder fillet to a tail on the bottom like traditional wave soldering, the through-hole component is a reflowed soldered from the top side. A tail that’s intended not to protrude the PBC is a feature found in pin-in-paste spring-loaded contacts which are being called a short stubby tail that is less which 1.5 mm in length. Since this type of SLC does not have a tail, it becomes much stronger in the mechanical area than an SMT SLC since it has bulls-eye alignment and the SLC cannot migrate on the PBC land during reflow.

There is much more to know about probe pins (pogo pins) but with many manufacturers around the market, you can find the best provider for you!